Induction Hardening is a method of providing fast & consistent hardening for manufacturing applications which involved bonding or changing properties of metlal for electrically conducting materials.

Toda's advanced design concepts warrant most engineering components to be heated to either from different shapes or attain specific grain structures.

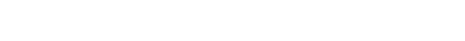

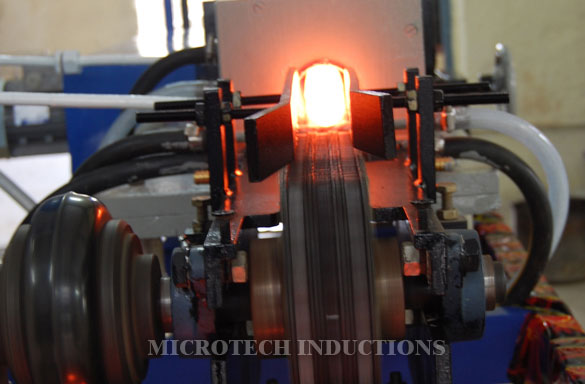

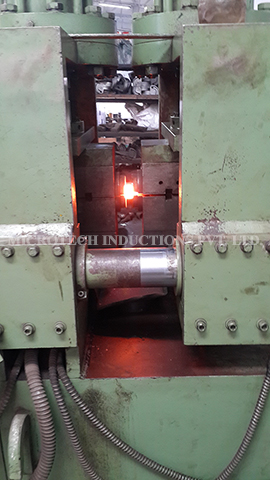

Microtech's range of induction hardening systems are offered for custom built applications with suitable coils, materials handling solutions with complete automation.

- Billet hardening for forging

- Surface hardening of tools

- Hardening of gear, auto parts, bolts cylinder bore and Crank shaft

- Bar end hardening

- Shrink Fitting

- Tang forging of files

- Diamond dresser manufacturing

- Tube bending

- Gattering of Vacuum tubes

- Sintering of copper powder

- Heating of graphite susceptor for MOCVD crystal growth.