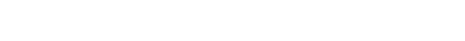

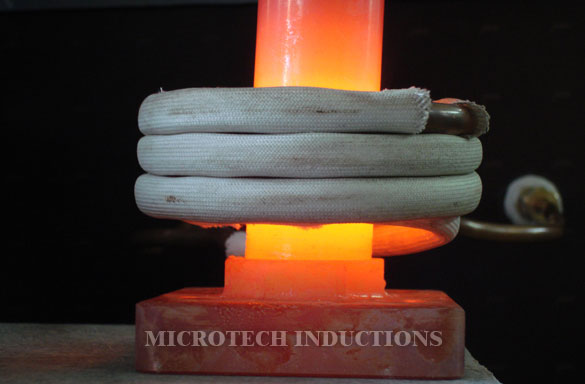

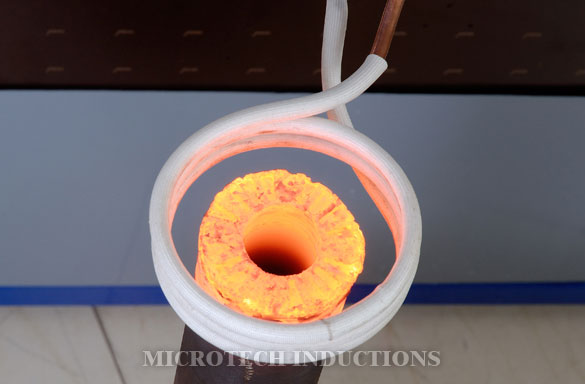

Brazing is joining of similar or dissimilar metal (parent materials) by using heat and braze material (filler material) whose melting temperture is normally above 450 C and below the melting temperature of parent materials being joined.

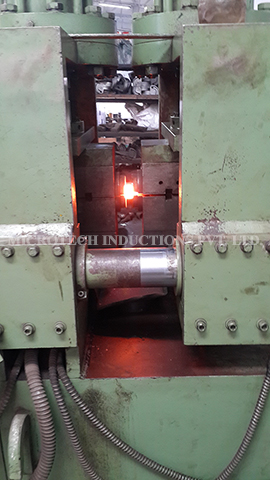

Microtech induction brazing machines are made to replace conventional brazing methods, with more reliable / repeatable brazing without flame and smoke.

Brazing temperature can be controlled from 450 C to 1200 C for most of the brazing applications.

- Copper parts for compressors.

- Copper components of transformers.

- Brass components.

- Submersible pump rotors.

- Ring cable lugs.

- Aluminium component joints.

- Soldering of brass components.

- Steel components joints.

- Brazing of storage water heater Elements.

- Diamond tipped cutting tools.

- Carbide tipping of cutting tools.

- Optical Frame Brazing.

- Fuel pipe Brazing.

- Vacuum brazing of critical components.

- Brazing stainless steel orthodontic parts.

- Brazing of stainless steel to Brass.

- Rocker Pins.

- Hydraulic Hose.